PEEK injection Ming-Li application

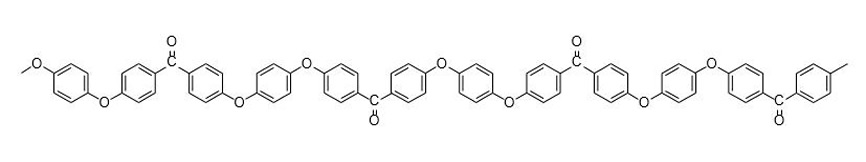

Poly(Ether Ether Ketone)

The Application Of our PEEK Injection Molding parts

Due to PEEK material has excellent comprehensive properties, it can replace traditional materials such as metals and ceramics in many special fields, making it one of the most popular high-performance plastic injection mold material today. It is currently mainly used in aerospace, automotive industry, electrical and electronic and medical machinery and other fields.

Automotive Industry

The growth of PEEK injection resin in the European market is especially the fastest growing in the automotive parts market. Especially the parts around the engine, variable speed transmission parts, steering parts, etc. have used PEEK injection molding parts instead of some traditional high-priced metals as the manufacturing material. As the automotive industry adapts to the requirements of miniaturization, light weight and cost reduction, the demand for PEEK injection molding parts will continue to grow.

PEEK (Polyetheretherketone) material finds several applications in the automotive industry due to its exceptional combination of properties, making it suitable for various critical components in vehicles. Here are some common applications of PEEK material in the automotive sector:

-

Engine Components: PEEK is used in automotive engine systems for manufacturing components such as seals, gaskets, thrust washers, and bearing cages. Its high temperature resistance, chemical inertness, and low friction coefficient make PEEK suitable for withstanding the extreme temperatures, pressures, and lubrication conditions encountered in internal combustion engines and transmission systems.

-

Fuel Systems: PEEK material is employed in automotive fuel system components such as seals, O-rings, and valve seats. Its resistance to fuels, oils, and hydraulic fluids make PEEK suitable for providing reliable sealing and fluid containment in fuel injection systems, fuel pumps, and fuel delivery components, ensuring safety and performance in automotive fuel systems.

-

Electrical and Electronic Components: PEEK is utilized in automotive electrical and electronic systems for manufacturing components such as connectors, insulators, and sensor housings. Its electrical insulation properties, dimensional stability, and resistance to moisture and chemicals make PEEK suitable for ensuring reliable electrical performance and signal integrity in automotive electronics, sensors, and control systems.

-

Interior Components: PEEK material finds application in automotive interior components such as seat frames, dashboard panels, and HVAC (Heating, Ventilation, and Air Conditioning) system parts. Its lightweight, flame-retardant properties, and resistance to chemicals and fluids make PEEK suitable for providing durable and aesthetically pleasing interior solutions while meeting safety and regulatory requirements.

-

Exterior Components: PEEK is used in automotive exterior components such as grille inserts, door handles, and mirror housings. Its high strength-to-weight ratio, impact resistance, and resistance to weathering and UV radiation make PEEK suitable for providing lightweight yet durable solutions for exterior styling and functionality, enhancing vehicle aesthetics and performance.

-

Transmission Systems: PEEK material finds application in automotive transmission systems for manufacturing components such as bushings, thrust washers, and shift forks. Its high mechanical strength, wear resistance, and low coefficient of friction make PEEK suitable for withstanding the high loads, speeds, and lubrication conditions encountered in automatic and manual transmissions, contributing to smooth and efficient gear shifting and power transmission.

-

Suspension and Steering Components: PEEK is utilized in automotive suspension and steering systems for manufacturing components such as bushings, bearings, and thrust washers. Its high strength, fatigue resistance, and dimensional stability make PEEK suitable for withstanding the dynamic loads and vibrations encountered in suspension and steering systems, contributing to vehicle stability, handling, and comfort.

Overall, PEEK material offers a range of properties such as high temperature resistance, chemical resistance, mechanical strength, and dimensional stability that make it well-suited for various automotive applications, contributing to the performance, reliability, and safety of vehicles.

Aerospace Industry

Even though aluminium is the material of choice for the aerospace industry, PEEK injection molding parts can still find application in some aircraft since it is lighter than aluminium. The only drawback is that PEEK injection molding parts is quite expensive to manufacture, yet it has even better recyclability than aluminium. Our high-performance PEEK injection molding parts solutions offer an exceptional combination of benefits to help aerospace OEMs, designers and processors reach new levels of cost savings, quality, and performance. Ming-Li solutions help lower weight, improve buy-to-fly ratios, and provide design freedom to optimise the design and consolidate parts.

PEEK (Polyetheretherketone) material finds numerous applications in the aerospace industry due to its exceptional combination of properties, making it suitable for critical components in aircraft, spacecraft, and related systems. Here are some common applications of PEEK material in the aerospace sector:

-

Structural Components: PEEK is used in the aerospace industry for manufacturing structural components such as brackets, clips, panels, and housings. Its high strength-to-weight ratio, stiffness, and fatigue resistance make PEEK suitable for applications where lightweight yet durable materials are required to withstand aerodynamic forces and structural loads.

-

Interior Components: PEEK material is employed in aircraft interiors for manufacturing components such as seat frames, tray tables, cabin panels, and overhead bins. Its lightweight, flame-retardant properties, and resistance to chemicals and fluids make PEEK suitable for providing durable and aesthetically pleasing interior solutions while meeting safety and regulatory requirements.

-

Engine Components: PEEK finds application in aircraft engine systems for manufacturing components such as seals, gaskets, thrust washers, and bearing cages. Its high temperature resistance, chemical inertness, and low friction coefficient make PEEK suitable for withstanding the extreme temperatures, pressures, and lubrication conditions encountered in jet engines and turbine systems.

-

Thermal Insulation: PEEK material is used in thermal insulation systems for spacecraft and satellite applications. Its low thermal conductivity and resistance to thermal degradation make PEEK suitable for providing thermal insulation and protection against temperature variations encountered in space environments, ensuring the integrity and performance of sensitive equipment and electronics.

-

Electrical and Electronic Components: PEEK is utilized in aerospace electrical and electronic systems for manufacturing components such as connectors, insulators, and housings. Its electrical insulation properties, dimensional stability, and resistance to radiation and electromagnetic interference (EMI) make PEEK suitable for ensuring reliable electrical performance and signal integrity in aerospace electronics and avionics systems.

-

Fuel System Components: PEEK material finds application in aerospace fuel system components such as seals, O-rings, and valve seats. Its resistance to aviation fuels, hydraulic fluids, and lubricants make PEEK suitable for providing reliable sealing and fluid containment in aircraft fuel systems, ensuring safety and performance during flight operations.

-

Composites and Additive Manufacturing: PEEK is used as a matrix material in advanced composites and additive manufacturing processes for producing lightweight and high-strength aerospace components. Its compatibility with carbon fibers, glass fibers, and other reinforcement materials allows for the fabrication of complex structures with tailored mechanical properties, contributing to weight reduction and fuel efficiency in aerospace applications.

Overall, PEEK material offers a range of properties such as high strength, lightweight, temperature resistance, chemical resistance, and dimensional stability that make it well-suited for various aerospace applications, contributing to the performance, reliability, and safety of aerospace systems and vehicles.

Oil & Gas Industry

PEEK polymer-based solutions can optimize production efficiency in hot, corrosive environments. Electrical connectors - greater reliability and performance. PEEK materials are increasingly being selected by connector OEMs to improve application performance, achieve more design freedom, and reduce downtime and system costs.

Higher insulation resistance than glass / Insulation integrity to negate electrical leakage / Great impact resistance for longer service life.

PEEK (Polyetheretherketone) material finds numerous applications in the oil and gas industry due to its exceptional combination of properties, making it suitable for demanding environments and critical components. Here are some common applications of PEEK material in the oil and gas sector:

-

Downhole Tools: PEEK is used in downhole drilling tools and equipment for manufacturing components such as seals, bearings, bushings, and wear rings. Its resistance to high temperatures, pressures, and corrosive fluids encountered in downhole environments makes PEEK suitable for withstanding the harsh conditions of oil and gas wells.

-

Valve Components: PEEK material is employed in valves and valve components for manufacturing seats, seals, packing rings, and bearings. Its resistance to chemicals, abrasion, and wear makes PEEK suitable for providing reliable sealing and smooth operation of valves in oil and gas processing, refining, and distribution systems.

-

Pump Components: PEEK is used in pumps and pumping systems for manufacturing components such as impellers, bearings, seals, and wear rings. Its resistance to abrasion, chemicals, and high temperatures makes PEEK suitable for withstanding the demanding conditions of pumping abrasive fluids, corrosive chemicals, and high-temperature fluids in oil and gas production and processing.

-

Sealing Systems: PEEK material finds application in sealing systems for manufacturing static and dynamic seals, gaskets, O-rings, and packings used in oil and gas equipment and pipelines. Its resistance to high pressures, temperatures, and aggressive chemicals makes PEEK suitable for providing reliable sealing and preventing leakage in critical applications.

-

Instrumentation and Control Systems: PEEK is utilized in instrumentation and control systems for manufacturing components such as sensors, connectors, housings, and electrical insulation. Its electrical insulation properties, dimensional stability, and resistance to chemicals and environmental factors make PEEK suitable for ensuring the reliability and performance of instrumentation and control systems in oil and gas facilities.

-

Subsea Equipment: PEEK material is used in subsea equipment and components for manufacturing connectors, fittings, seals, and housings. Its resistance to seawater, corrosion, and hydrostatic pressure makes PEEK suitable for withstanding the harsh conditions encountered in subsea oil and gas production, exploration, and drilling operations.

-

Drilling and Completion Tools: PEEK is employed in drilling and completion tools for manufacturing components such as centralizers, casing spacers, and liners. Its high mechanical strength, thermal stability, and resistance to abrasion make PEEK suitable for providing support, alignment, and protection in drilling and completion operations.

Overall, PEEK material offers a range of properties such as high mechanical strength, chemical resistance, thermal stability, and dimensional stability that make it well-suited for various applications in the oil and gas industry, contributing to the reliability, efficiency, and safety of oil and gas exploration, production, processing, and distribution operations.

Defense Industry

The PEEK material is widely using in defens industry. There are many PEEK injection molding parts in the defens industry. For example: PEEK molding connector parts, etc.

PEEK (Polyetheretherketone) material finds several applications within the defense industry due to its exceptional combination of properties, making it suitable for various critical components and systems. Here are some common applications of PEEK material in the defense sector:

-

Aircraft Components: PEEK is used in the aerospace and defense industries for manufacturing various aircraft components, including structural parts, interior components, engine components, and electrical connectors. Its lightweight, high strength-to-weight ratio, and resistance to aerospace fluids and fuels make PEEK suitable for applications requiring weight reduction, durability, and performance.

-

Missile Systems: PEEK material is employed in missile systems for manufacturing structural components, guidance systems, electronic housings, and thermal management components. Its high mechanical strength, thermal stability, and resistance to harsh environments make PEEK suitable for withstanding the extreme conditions encountered during missile launch, flight, and operation.

-

Ballistic Protection: PEEK is used in ballistic protection systems for manufacturing lightweight armor plates, helmets, and protective gear for military personnel. Its high tensile strength, impact resistance, and energy absorption properties make PEEK suitable for providing ballistic protection against projectiles and fragments while minimizing weight and bulkiness.

-

Weapon Systems: PEEK material finds application in weapon systems for manufacturing components such as firearm parts, weapon housings, and tactical equipment. Its high strength, dimensional stability, and resistance to wear and corrosion make PEEK suitable for withstanding the rigors of weapon operation and maintenance in military environments.

-

Communication Systems: PEEK is utilized in communication systems for manufacturing antenna components, RF (Radio Frequency) connectors, and electronic housings. Its electrical insulation properties, low dielectric constant, and resistance to electromagnetic interference (EMI) make PEEK suitable for ensuring reliable communication and signal integrity in military communication systems.

-

Submarine Components: PEEK material is used in submarine systems for manufacturing components such as pressure hulls, valve seals, and underwater connectors. Its resistance to seawater, corrosion, and hydrostatic pressure make PEEK suitable for withstanding the harsh conditions encountered in submarine operations and ensuring the integrity and reliability of critical systems.

-

Vehicle Armor: PEEK is employed in vehicle armor systems for manufacturing lightweight armor panels, blast-resistant components, and vehicle interiors. Its high strength, impact resistance, and energy absorption properties make PEEK suitable for providing protection against ballistic threats, improvised explosive devices (IEDs), and mine blasts while minimizing the weight and fuel consumption of military vehicles.

Overall, PEEK material offers a range of properties such as high mechanical strength, lightweight, thermal stability, chemical resistance, and dimensional stability that make it well-suited for various defense applications, contributing to the performance, reliability, and safety of defense systems and personnel.

Pump Industry

The PEEK material is widely using in pump industry. There are many PEEK material part in the pump. For example: PEEK bushing, PEEK gear, etc.

Pumps used in various industries, including chemical processing, oil and gas, pharmaceuticals, and automotive, often encounter demanding operating conditions such as high temperatures, corrosive chemicals, and abrasive fluids. In such applications, traditional pump materials like metals or standard plastics may not offer the required performance or longevity. Here's why PEEK material is often chosen for pump applications:

-

Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons. This resistance makes it ideal for handling corrosive fluids in chemical processing, pharmaceutical, and oil and gas applications without degradation or material breakdown.

-

Temperature Resistance: PEEK exhibits excellent thermal stability, maintaining its mechanical properties over a wide temperature range (-40°C to 250°C or higher). This makes it suitable for pump applications where high temperatures are encountered, such as in industrial processes or automotive cooling systems.

-

Mechanical Strength: PEEK has exceptional mechanical properties, including high tensile strength, stiffness, and fatigue resistance. These properties allow PEEK components in pumps to withstand high-pressure environments and mechanical stresses without deformation or failure, ensuring long-term reliability and durability.

-

Wear Resistance: PEEK exhibits low friction and excellent wear resistance, even in abrasive environments. This property is beneficial for pump components such as bearings, bushings, seals, and impellers, where friction and wear can lead to premature failure or reduced efficiency.

-

Dimensional Stability: PEEK has excellent dimensional stability, meaning it maintains its shape and size even under varying temperature and pressure conditions. This property ensures tight tolerances and consistent performance of pump components, contributing to efficient operation and reduced downtime.

-

Biocompatibility: In certain pump applications, particularly in the pharmaceutical and medical industries, biocompatibility is essential. PEEK is biocompatible and suitable for contact with human tissues and fluids, making it ideal for applications where sterility and compatibility are critical.

-

Lightweight: Compared to metals, PEEK is lightweight, which can reduce the overall weight of the pump system. This is advantageous in automotive and aerospace applications, where weight savings contribute to fuel efficiency or payload capacity.

-

Ease of Processing: PEEK is amenable to injection molding, allowing for complex geometries and precise manufacturing of pump components. Injection molding enables cost-effective production of custom-designed parts with reduced lead times, making it attractive for pump manufacturers.

In summary, PEEK material offers a combination of chemical resistance, temperature resistance, mechanical strength, wear resistance, dimensional stability, biocompatibility, and ease of processing that make it well-suited for demanding pump applications across various industries. Its performance benefits contribute to improved reliability, efficiency, and longevity of pump systems.

Semiconductor equipment

PEEK material helps shape the future performance of semiconductor technologies by offering increased productivity, reliability and reduced risks by lower particle generation and outgassing. High wear resistance allows CMP retainer rings made from PEEK to run up to two times longer than PPS before replacing, leading to less downtime and more throughput. The properties of PEEK polymers including wear and chemical resistance, dimensional stability, ESD, and low outgassing can help prevent particle contamination and achieve more reliable wafer handling, storage, and transfer.

PEEK (Polyetheretherketone) material finds various applications in semiconductor technology due to its unique combination of properties, making it suitable for demanding requirements in this field. Some common applications of PEEK material in semiconductor technology include:

-

Wafer Handling and Processing Equipment: PEEK is used in the construction of wafer handling and processing equipment due to its excellent chemical resistance and high-temperature stability. Components such as wafer carriers, handling trays, and process chambers made from PEEK can withstand exposure to harsh chemicals and high temperatures encountered during semiconductor fabrication processes.

-

Lithography Equipment: PEEK is employed in lithography equipment components such as mask holders, alignment systems, and stage components. Its dimensional stability, low outgassing, and resistance to photoresist chemicals make it suitable for use in critical lithography processes, ensuring precise alignment and positioning of semiconductor wafers.

-

Test Sockets and Handlers: PEEK material is used to manufacture test sockets and handlers for semiconductor testing and validation. Its high mechanical strength, wear resistance, and electrical insulation properties enable reliable contact and testing of semiconductor devices, including integrated circuits (ICs) and microchips, during production and quality assurance processes.

-

Cleanroom Components: PEEK is preferred for fabricating cleanroom components such as chambers, covers, and fixtures due to its low particle generation, chemical inertness, and ease of cleaning. These components help maintain the cleanliness and integrity of semiconductor manufacturing environments, reducing contamination risks and ensuring high product quality.

-

Gas Distribution Systems: PEEK is utilized in gas distribution systems for delivering process gases to semiconductor processing equipment. Its resistance to corrosion, thermal stability, and compatibility with a wide range of chemicals make it suitable for use in gas panels, manifolds, valves, and fittings, ensuring reliable and contamination-free gas delivery.

-

Wire Bonding and Encapsulation: PEEK material is employed in wire bonding and encapsulation applications for semiconductor packaging. Its high dielectric strength, thermal stability, and resistance to moisture and chemicals make it suitable for encapsulating semiconductor devices and providing electrical insulation and environmental protection.

-

Test Sockets and Handlers: PEEK material is used to manufacture test sockets and handlers for semiconductor testing and validation. Its high mechanical strength, wear resistance, and electrical insulation properties enable reliable contact and testing of semiconductor devices, including integrated circuits (ICs) and microchips, during production and quality assurance processes.

-

Vacuum Chamber Components: PEEK is utilized in vacuum chamber components such as seals, gaskets, and insulators due to its low outgassing characteristics, high temperature resistance, and compatibility with vacuum environments. These components help maintain vacuum integrity and prevent contamination in semiconductor processing equipment.

Overall, PEEK material offers a combination of properties such as chemical resistance, thermal stability, mechanical strength, and dimensional stability that make it well-suited for various applications in semiconductor technology, contributing to the efficiency, reliability, and performance of semiconductor manufacturing processes.

PEEK Gear

For the separation claws of copiers, special heat-resistant bearings, chains, gears, etc., when PEEK resin is used instead of metal as their material, the components can be lightweight, fatigue-resistant, and can be lubricated without oil.

PEEK (Polyetheretherketone) material is well-suited for gear applications due to its exceptional combination of properties, making it suitable for demanding mechanical and environmental conditions. Here are some common applications of PEEK material in gear parts:

-

Automotive Gears: PEEK is used in automotive transmission systems for manufacturing gears, particularly in high-performance vehicles. Its high mechanical strength, wear resistance, and temperature stability allow PEEK gears to withstand the rigors of engine power transmission, providing durability and reliability.

-

Aerospace Gears: PEEK material finds application in aerospace gear systems, including aircraft engines, landing gear mechanisms, and auxiliary power units (APUs). Its lightweight, high strength-to-weight ratio, and resistance to aerospace fluids and lubricants make PEEK gears suitable for aerospace applications where weight reduction and performance are critical.

-

Industrial Gears: PEEK gears are utilized in various industrial machinery and equipment, including pumps, compressors, actuators, and gearboxes. Its excellent wear resistance, low friction coefficient, and dimensional stability ensure smooth and efficient operation of gear systems in industrial environments with high loads and speeds.

-

Medical Gears: PEEK material is used in medical equipment and devices for manufacturing gears used in surgical instruments, diagnostic equipment, and implantable devices. Its biocompatibility, chemical resistance, and sterilizability make PEEK gears suitable for medical applications where precision, reliability, and compatibility with biological tissues are essential.

-

Oil and Gas Gears: PEEK gears are employed in oil and gas drilling and extraction equipment for withstanding harsh operating conditions such as high temperatures, pressure, and corrosive environments. Its resistance to hydrocarbons, chemicals, and abrasion make PEEK gears suitable for use in downhole drilling tools, pumps, valves, and actuators.

-

Marine Gears: PEEK material is used in marine propulsion systems, including boat engines, propellers, and thrusters. Its resistance to saltwater, corrosion, and marine environments, along with its high strength and fatigue resistance, make PEEK gears suitable for marine applications where durability and performance are critical.

-

Power Transmission Gears: PEEK gears are utilized in power transmission systems, including electric motors, generators, and motion control systems. Its electrical insulation properties, low coefficient of friction, and resistance to wear and abrasion ensure reliable and efficient power transmission in various industrial and automotive applications.

Overall, PEEK material offers a range of properties such as high mechanical strength, wear resistance, temperature stability, chemical resistance, and dimensional stability that make it well-suited for gear applications across industries, providing durable, reliable, and high-performance gear solutions.

Bearings Applications

Reliable insulation of bearings is key to ensure efficient performance over the component lifetime. Using PEEK material to overmould bearings helps address reliable electrical insulation of large or small bearings and potentially reduces component cost.

PEEK (Polyetheretherketone) material finds several applications in the bearings industry due to its exceptional combination of properties, making it suitable for various bearing applications where high performance, durability, and reliability are required. Here are some common applications of PEEK material in the bearings industry:

-

High-Temperature Bearings: PEEK is used to manufacture high-temperature bearings for applications where conventional bearing materials such as steel or bronze would fail due to elevated temperatures. PEEK's excellent thermal stability allows it to maintain its mechanical properties and dimensional stability at temperatures exceeding 250°C (482°F), making it suitable for use in automotive engines, aerospace systems, and industrial machinery operating under extreme heat conditions.

-

Chemical Resistant Bearings: PEEK bearings are employed in applications where exposure to corrosive chemicals, solvents, or aggressive fluids is a concern. PEEK's inherent chemical resistance allows it to withstand a wide range of chemicals, including acids, bases, fuels, and lubricants, making it suitable for use in chemical processing equipment, laboratory instruments, and pumps where compatibility with aggressive media is critical.

-

Low-Friction Bearings: PEEK material is used to manufacture bearings with low friction and wear properties, reducing energy consumption, minimizing heat generation, and extending component life. PEEK's low coefficient of friction and self-lubricating properties make it suitable for applications where smooth and efficient operation is required, such as conveyor systems, textile machinery, and medical devices.

-

High-Speed Bearings: PEEK bearings are utilized in high-speed applications where rotational speeds exceed the capabilities of traditional bearing materials. PEEK's high strength, stiffness, and resistance to deformation enable it to withstand the centrifugal forces and dynamic loads associated with high-speed operation, making it suitable for use in precision instruments, turbochargers, and aerospace systems.

-

Lightweight Bearings: PEEK material is used to manufacture lightweight bearings for applications where weight reduction is a priority, such as automotive, aerospace, and marine systems. PEEK's low density and high strength-to-weight ratio allow for the design of lightweight and compact bearing assemblies, contributing to fuel efficiency, performance, and payload capacity in various applications.

-

Electrically Insulating Bearings: PEEK bearings find application in electrical and electronic systems where electrical insulation is required to prevent electrical arcing, short circuits, or electromagnetic interference (EMI). PEEK's high dielectric strength and electrical insulation properties make it suitable for use in electric motors, generators, transformers, and semiconductor manufacturing equipment.

-

Medical and Biomedical Bearings: PEEK material is employed in medical and biomedical applications for manufacturing bearings used in surgical instruments, prosthetic devices, and medical implants. PEEK's biocompatibility, chemical inertness, and resistance to sterilization methods make it suitable for use in medical environments where compatibility with biological tissues and fluids is essential.

Overall, PEEK material offers a range of properties such as high temperature resistance, chemical resistance, low friction, high strength, lightweight, and electrical insulation that make it well-suited for various bearing applications across industries, providing durable, reliable, and high-performance bearing solutions.

Medial Applications

In the field of medical analysis equipment, PEEK can withstand repeated autoclaving, and it can be used to manufacture endoscope parts and dental cleaners in medical equipment. In addition, due to the high strength and low dissolution of PEEK, it has been used in liquid chromatography columns, tubes, and accessories for instrument analysis. Moreover, because PEEK has good compatibility with the human body, it has successfully replaced traditional titanium as an artificial bone material.

PEEK (Polyetheretherketone) material is widely used in the medical industry due to its exceptional combination of properties, making it suitable for various medical applications where biocompatibility, sterilizability, and performance are critical. Here are some common applications of PEEK material in the medical industry:

-

Orthopedic Implants: PEEK is used to manufacture orthopedic implants such as spinal cages, interbody fusion devices, and orthopedic screws. Its biocompatibility, radiolucency, and mechanical properties similar to bone make PEEK an excellent material for implants that promote bone fusion, stability, and patient comfort. PEEK implants also allow for clear imaging in X-rays and MRI scans, facilitating postoperative evaluation.

-

Dental Devices: PEEK material is employed in dental applications for manufacturing dental implants, prosthetic components, and orthodontic appliances. Its biocompatibility, tooth-colored appearance, and ease of machining make PEEK suitable for dental restorations, crowns, bridges, and denture frameworks. PEEK dental implants offer excellent osseointegration and long-term stability in the oral environment.

-

Surgical Instruments: PEEK is used to manufacture surgical instruments and devices such as forceps, retractors, scalpel handles, and surgical trays. Its biocompatibility, chemical resistance, and sterilizability make PEEK suitable for repeated autoclaving, steam sterilization, and ethylene oxide (EtO) sterilization methods without compromising performance or integrity.

-

Medical Device Components: PEEK material is utilized in various medical devices and equipment components, including catheters, connectors, tubing, and fluid handling systems. Its biocompatibility, flexibility, low friction, and resistance to chemicals and bodily fluids make PEEK suitable for use in minimally invasive procedures, intravenous (IV) administration, and patient monitoring applications.

-

Spinal Implants and Instrumentation: PEEK is extensively used in spinal surgery for manufacturing spinal implants, rods, plates, and pedicle screws. Its radiolucency, biocompatibility, and modulus of elasticity similar to bone make PEEK an ideal material for spinal fusion devices that minimize stress shielding, reduce artifact interference in imaging, and promote bone healing.

-

External Fixation Devices: PEEK material is employed in external fixation devices for stabilizing fractures, correcting deformities, and promoting bone regeneration. Its lightweight, high strength, and radiolucency make PEEK suitable for manufacturing external fixators, pins, and clamps that provide rigid fixation while allowing for clear visualization of the healing process.

-

Surgical Implant Delivery Systems: PEEK is used to manufacture surgical implant delivery systems such as insertion instruments, guidewires, and implantation tools. Its strength, stiffness, and compatibility with sterilization methods make PEEK suitable for delivering and positioning implants with precision and control during surgical procedures.

Overall, PEEK material offers a range of properties such as biocompatibility, radiolucency, sterilizability, mechanical strength, and chemical resistance that make it well-suited for various medical applications, contributing to the development of innovative medical devices, implants, and instrumentation that improve patient outcomes, surgical outcomes, and quality of life.

Electrical Applications

PEEK is an excellent electrical insulator and retains its mechanical properties at high temperatures. It can thus find application in electrical instruments that operate at high temperatures, such as soldering machines.

PEEK (Polyetheretherketone) material is widely utilized in electrical applications due to its excellent combination of properties, making it suitable for various electrical components and systems. Here are some common applications of PEEK material in the electrical industry:

-

Electrical Insulation: PEEK is used as an electrical insulating material in high-voltage applications, such as transformers, switchgear, and power distribution systems. Its high dielectric strength, low dielectric constant, and resistance to electrical breakdown make it suitable for providing insulation and preventing electrical arcing or short circuits.

-

Connector Components: PEEK material is employed in electrical connectors, terminals, and housings for electronic devices, telecommunications equipment, and automotive electrical systems. Its high mechanical strength, dimensional stability, and resistance to wear and corrosion make it suitable for providing reliable electrical connections and protecting sensitive electronic components from environmental factors.

-

Printed Circuit Boards (PCBs): PEEK is used in the manufacturing of PCB substrates and insulating materials for electronic circuits. Its excellent thermal stability, low moisture absorption, and resistance to soldering temperatures make it suitable for use in high-temperature applications, such as surface-mount technology (SMT) and lead-free soldering processes.

-

Wire and Cable Coatings: PEEK material is utilized as a coating or insulation material for wires, cables, and harnesses in aerospace, automotive, and industrial applications. Its abrasion resistance, chemical resistance, and thermal stability allow it to protect wires and cables from mechanical damage, environmental exposure, and high-temperature conditions, ensuring reliable electrical performance and longevity.

-

Sensor Components: PEEK is used in sensor components and housings for measuring instruments, control systems, and industrial automation equipment. Its dimensional stability, chemical resistance, and compatibility with various sensing technologies make it suitable for providing protection and encapsulation for sensors used in harsh environments, such as chemical processing plants, oil and gas refineries, and automotive engine systems.

-

Fuse Components: PEEK material is employed in fuse components, such as fuse holders, fuse blocks, and fuse clips, for electrical protection devices in power distribution systems and electronic equipment. Its high temperature resistance, mechanical strength, and flame-retardant properties make it suitable for providing reliable and durable electrical connections and thermal protection in fuse assemblies.

-

Insulating Bushings and Spacers: PEEK is used to manufacture insulating bushings, spacers, and standoffs for electrical equipment and components. Its high dielectric strength, creep resistance, and dimensional stability allow it to provide electrical insulation and mechanical support in applications requiring precise spacing, alignment, and isolation of conductive elements.

Overall, PEEK material offers a range of properties such as high temperature resistance, chemical resistance, electrical insulation, mechanical strength, and dimensional stability that make it well-suited for various electrical applications, contributing to the performance, reliability, and safety of electrical systems and components.

PEEK™ Specify

- High temperature performance

- Mechanicals / Fatigue

- FDA approved

- Acoustic properties

- Radiation resistance

- Low moisture absorption

- Hydrolysis resistance

- Good flame performance

- Electrical properties

- Barrier properties – moisture & gas

- Low toxicity of smoke

- Wear and friction

- Chemical resistance

- RoHS compliant, halogen free

- Versatile secondary process capability

- Light weight