Gas Assist Injection Molding

Application: Automotive Industry in global Automobile

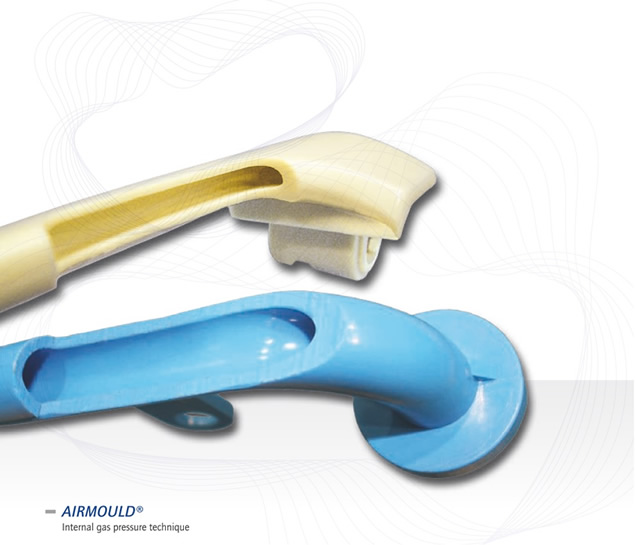

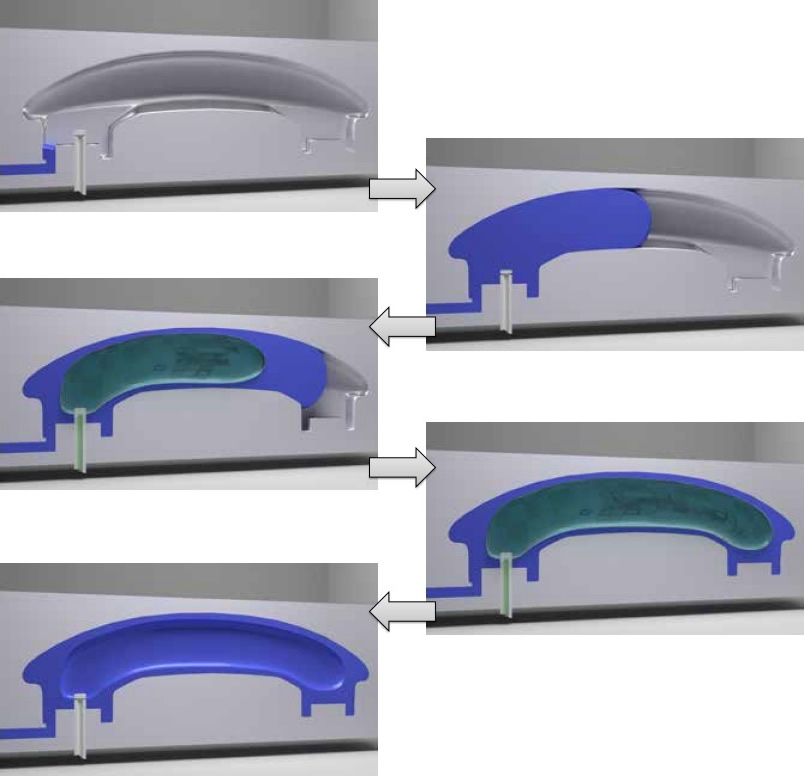

The gas injection displaces the molten polymer core ahead of the gas, into the as yet unfilled sections of the mold, and compensates for the effects of volumetric shrinkage, thus completing the filling and packing phases of the cycle and producing a hollow part.

Traditionally, injection molded components have been designed with a relatively constant wall thickness throughout the component. This design guideline helps to avoid major flaws or defects such as sink marks and warpage. However, apart from the simplest of parts, it is impossible to design a component where all sections are of identical thickness. These variations in wall thickness result in different sections of the part packing differently, which in turn means that there will be differentials in shrinkage throughout the molding and that subsequently distortion and sinkage can often occur in these situations.

Maximum clamp pressures are normally required during the packing phase of a molding cycle. This is due to the force which has to be exerted at the polymer gate in order to pack melt into the extremities of the mold cavity in an effort to compensate for the volumetric shrinkage of the solidifying melt. In comparison to compact injection molding, gas injection molding typically has considerably shorter distance over which the solidifying melt is required to be packed because of the gas core. This means that proportionally lower packing pressures are required to achieve the same results and in turn, lower machine clamp forces are required.

Gas injection allows cost effective production of components with:

- Thick section geometry

- No sink marks

- Minimal internal stresses

- Reduced warpage

- Low clamp pressures

Gas-assisted Fill+Pack analysis benefits

Gas-assisted Fill+Pack analysis provides you with the ability to study polymer and gas flow behavior within a part model and examine the influence that design modifications make on both the polymer and gas flow paths.

Using this information, the design engineer will be able to optimize product design and accurately position polymer and gas injection points. Also to ensure that the product specifications are met, utilizing the full capabilities of the gas injection molding process. Expensive tool modifications, long lead times and trial and error will also be kept to a minimum.

The process engineer will benefit from the program’s capacity to examine the effects that varying processing conditions will have on the component and enable optimum processing conditions to be established prior to mold commissioning.

Gas assist injection molding is a process used to produce complex, hollow plastic parts with reduced material usage, improved surface finish, and reduced cycle times. Here's how the process generally works:

-

Injection Stage: The process begins like traditional injection molding, where plastic resin pellets are fed into the injection molding machine's hopper. The pellets are then heated and melted in the barrel of the machine, forming a viscous molten material.

-

Injection into the Mold: Once the molten plastic reaches the desired temperature and consistency, it is injected into a mold cavity under high pressure. The mold is typically designed with features and geometry to create the desired shape of the final part, including any internal voids or hollow sections.

-

Gas Injection Stage: As the molten plastic fills the mold cavity, a controlled volume of inert gas (usually nitrogen) is injected into the center of the molten plastic through a gas injection port or nozzle. The gas displaces the molten plastic from the center of the part, forcing it to flow and pack out against the mold walls.

-

Pressure Maintenance and Cooling: Once the gas injection is complete, the gas pressure is maintained for a short period to hold the plastic against the mold walls and prevent sink marks or warpage as the part cools and solidifies. The mold is then cooled using water channels to accelerate the solidification process.

-

Part Ejection: After the plastic has fully cooled and solidified, the mold opens, and the finished part is ejected from the mold cavity. The gas trapped within the hollow sections of the part is typically vented or released as the mold opens.

-

Secondary Operations (if necessary): Depending on the part design and requirements, secondary operations such as trimming, drilling, or assembly may be performed to finalize the part.

The key benefits of gas assist injection molding include:

- Reduced material usage: Gas assist allows for hollow sections within the part, reducing material consumption compared to solid parts.

- Improved part quality: Gas assist helps reduce sink marks, warpage, and surface defects by providing uniform pressure during cooling.

- Enhanced design flexibility: The process enables the production of complex parts with intricate geometries and internal features.

- Shortened cycle times: Gas assist can reduce cycle times by accelerating the cooling process and allowing for faster injection speeds.

Gas assist injection molding is commonly used in various industries, including automotive, consumer goods, electronics, and medical devices, to produce a wide range of parts such as automotive components, appliance housings, handles, and enclosures.

This is just a partial overview of Gas Assist Injection Molding. Are they the right solutions for you? Not sure how to apply them to your next project? Just contact our technical experts and we can offer helpful advice about how to get the best results from both processes.