Micro molding / Micro injection molding

We made it high precision.

Monthly Capacity : 15 sets / Dies. 15 million pcs / Micro molding & Micor Injection parts

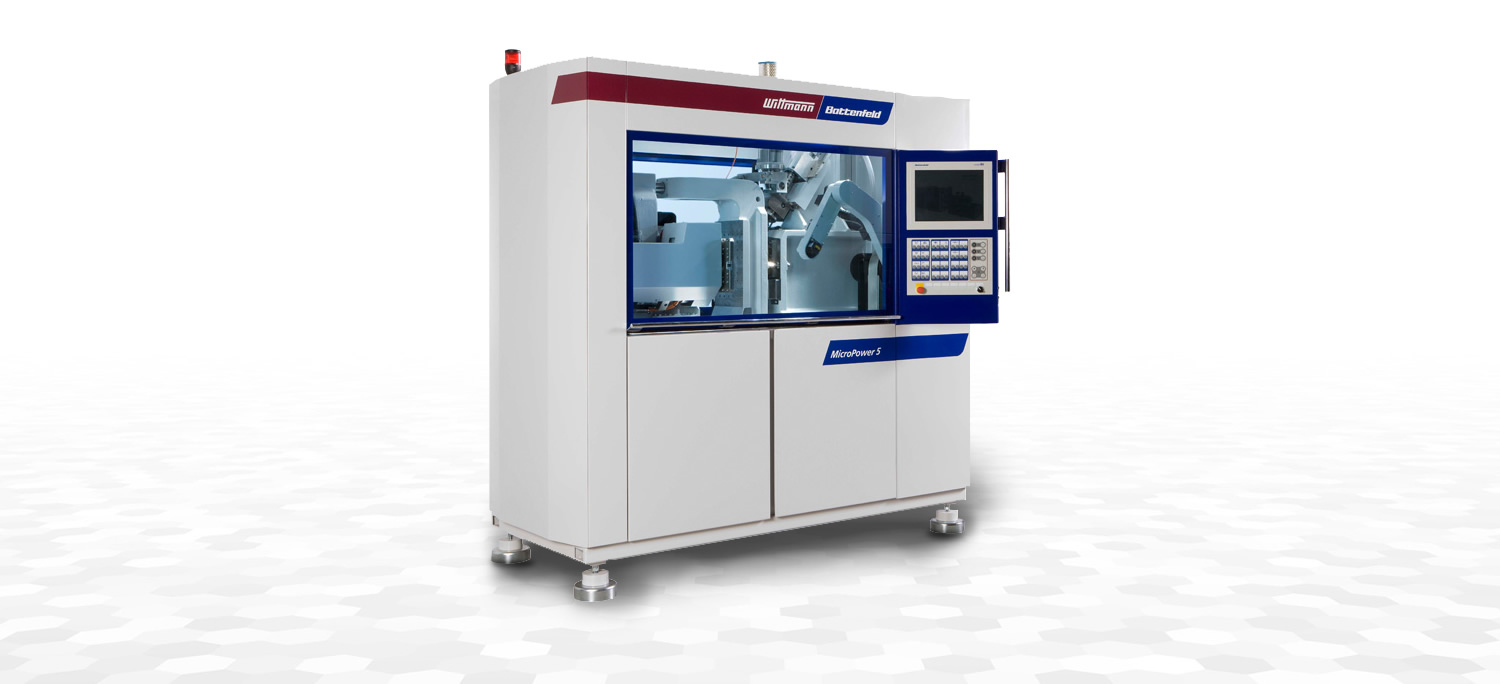

Through shorter cycle times and lower material and energy consumption, cost savings between 30 and 50 % can be achieved compared to standardmachines.

This concept makes it possible to extend a basic machine model – starting from a simple “general purpose machine” for small parts – to a multi-functional production cell for highly complex micro injection parts, just by connecting modules.

Clean room-compatible standard concept

The standard machine frame is designed for easy cleaning. Without any structural alterations it can be combined with a laminar flow unit, which supplies class 6 clean air according to ISO 14644-1 standard.COMBIMOULD

Advantages :

- Cost- and energy-efficient, economizing on resources.

- Outstanding parts quality through processing thermally homogeneous melt.

- Processing of all injectable materials with shot volumes of up to 4 cm³.

- Precise and powerful.

- Clean room-compatible standard concept.

- Also available in COMBMOULD version.

Key elements for micro molding

Micro injection molding is a specialized manufacturing process used to produce small, intricate plastic components with high precision and accuracy. Key elements for successful micro injection molding include:

-

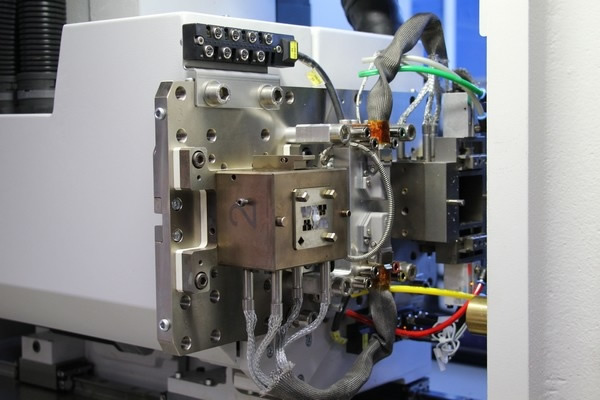

Tooling Design: The design of the mold is critical in micro injection molding. It must be precision-engineered to accommodate the small size and intricate features of the micro components. Tooling considerations include cavity design, gate placement, part ejection, and cooling channels to ensure consistent part quality and dimensional accuracy.

-

Material Selection: Choosing the right material is crucial in micro injection molding. Materials with excellent flow characteristics, low viscosity, and high dimensional stability are preferred for producing small, intricate parts. Thermoplastics such as ABS, PC, PMMA, and various engineering resins are commonly used in micro injection molding.

-

Injection Molding Machine: Micro injection molding requires specialized injection molding machines equipped with high-precision controls and micro-scale capabilities. These machines are designed to deliver precise shot volumes, accurate injection pressures, and tight temperature control to produce micro parts with high repeatability.

-

Tooling and Process Validation: Validation of tooling design and process parameters is essential in micro injection molding to ensure part quality and consistency. Mold flow analysis, mold trials, and process optimization are conducted to validate tooling design and establish optimal process conditions.

-

Injection Molding Process Parameters: Optimizing injection molding process parameters is critical for achieving uniform filling of the mold cavities and precise replication of micro features. Process parameters such as temperature, pressure, injection speed, and cooling time are carefully controlled to minimize defects and achieve tight tolerances.

-

Material Handling and Dosing: Material handling and dosing systems are crucial in micro injection molding to ensure accurate and consistent shot volumes. Micro-scale dosing units and precision metering systems are used to deliver small quantities of material with high precision and repeatability.

-

Tooling Maintenance and Cleaning: Proper maintenance and cleaning of the mold are essential to prevent contamination and ensure consistent part quality. Micro injection molding tooling requires regular inspection, cleaning, and maintenance to remove residue, prevent wear, and extend tool life.

-

Quality Control and Inspection: Implementing robust quality control measures and inspection procedures is essential in micro injection molding to verify part dimensions, surface finish, and material properties. Advanced metrology equipment, such as optical microscopes and coordinate measuring machines (CMMs), are used to inspect micro parts with high precision and accuracy.

-

Part Handling and Packaging: Micro injection molded parts require careful handling and packaging to prevent damage or distortion. Automated part handling systems and custom packaging solutions are used to ensure the safe transport and storage of micro parts.

By addressing these key elements effectively, manufacturers can optimize the micro injection molding process to produce small, intricate plastic components with high precision, accuracy, and repeatability for a wide range of applications in industries such as medical devices, electronics, automotive, and consumer goods.

Molds request for micro molding

Molds for micro molding, also known as micro molds, are specialized tools designed to produce small, intricate plastic components with high precision and accuracy. These molds are engineered to accommodate the unique challenges of micro molding, including small part size, tight tolerances, and intricate geometries. Here are some key characteristics and considerations for molds used in micro molding:

-

High Precision and Accuracy: Micro molds must be manufactured with extremely high precision to achieve tight tolerances and accurate replication of micro features. This requires advanced machining techniques, such as micro-milling, EDM (electrical discharge machining), or laser machining, to produce intricate cavities and fine details with sub-micron accuracy.

-

Small Size and Complexity: Micro molds are typically smaller in size compared to conventional injection molds and may contain complex geometries, micro features, and intricate details. The design and manufacturing of micro molds must account for these factors to ensure proper mold filling, cooling, and part ejection without compromising part quality.

-

Multi-Cavity Design: To maximize productivity and efficiency, micro molds often incorporate multiple cavities to produce multiple parts in each molding cycle. However, designing multi-cavity micro molds presents additional challenges related to balancing cavity pressures, maintaining uniform filling, and ensuring consistent part quality across all cavities.

-

Hot Runner Systems: Hot runner systems are commonly used in micro molds to maintain precise temperature control of the molten plastic and minimize material waste. Micro-sized hot runner systems with ultra-fine nozzles and small manifold channels are employed to deliver small shot volumes with high accuracy and repeatability.

-

Material Compatibility: Micro molds must be compatible with the specific thermoplastic materials used in micro molding applications. Materials with low viscosity, excellent flow properties, and high dimensional stability are preferred for producing small, intricate parts. The mold material must also be capable of withstanding high temperatures and pressures during the injection molding process.

-

Tooling Materials: Micro molds are typically made from high-performance tool steels, such as P20, H13, or stainless steel, to withstand the rigors of high-speed injection molding and maintain dimensional stability over numerous molding cycles. Some micro molding applications may require advanced materials, such as ceramic or titanium, to achieve ultra-high precision and durability.

-

Surface Finish and Texture: The surface finish of micro molds is critical for achieving smooth, defect-free parts with high-quality surface aesthetics. Molds may undergo additional finishing processes, such as polishing, texturing, or coating, to achieve the desired surface finish and texture on the molded parts.

-

Mold Cooling and Temperature Control: Efficient mold cooling is essential for controlling cycle times, minimizing warpage, and ensuring consistent part quality in micro molding. Micro molds may incorporate intricate cooling channels, conformal cooling, or advanced cooling technologies to achieve optimal temperature control and uniform cooling throughout the mold cavity.

-

Tooling Maintenance and Cleaning: Proper maintenance and cleaning of micro molds are essential to prevent contamination, extend tool life, and ensure consistent part quality. Micro molds require regular inspection, cleaning, and maintenance to remove residue, prevent wear, and optimize mold performance over time.

Overall, micro molds play a crucial role in the success of micro molding applications, enabling the production of small, intricate plastic components with high precision, accuracy, and repeatability for a wide range of industries and applications.

Molds design for micro molding

Designing for micro molding requires careful consideration of various factors to ensure successful production of small, intricate plastic components with high precision and accuracy. Here are key considerations for designing for micro molding:

-

Part Geometry: Design parts with simplified geometries and minimal features to accommodate the limitations of micro molding. Avoid sharp corners, undercuts, and complex geometries that may be difficult to mold accurately at a small scale.

-

Wall Thickness: Maintain uniform wall thickness throughout the part to minimize flow variations and achieve consistent filling during molding. Thinner walls help reduce cycle times and material usage while ensuring part integrity.

-

Draft Angles: Incorporate draft angles into part designs to facilitate easy ejection from the mold cavity. Draft angles help prevent sticking and reduce the risk of damage to delicate features during ejection.

-

Feature Size and Tolerances: Specify feature sizes and tolerances within the capabilities of micro molding processes. Consider the limitations of mold cavities, tooling, and material flow when defining part dimensions and tolerances.

-

Material Selection: Choose materials suitable for micro molding applications, such as engineering thermoplastics with good flow properties, dimensional stability, and compatibility with the molding process. Consider factors like temperature resistance, strength, and surface finish requirements when selecting materials.

-

Gate Design: Optimize gate design for efficient filling and minimal part distortion. Use small, precise gates positioned strategically to ensure uniform flow of molten plastic and minimize gate vestige on the finished part.

-

Surface Finish: Specify desired surface finish requirements based on the application and aesthetics of the part. Consider secondary processes like polishing, texturing, or coating to achieve the desired surface finish and improve part functionality.

-

Undercuts and Features: Minimize or eliminate undercuts and intricate features that may require complex mold actions or secondary operations. Simplify part designs to reduce tooling complexity and production costs.

-

Mold Design Considerations: Collaborate with mold designers to optimize mold designs for micro molding. Consider factors like mold material, gating, cooling, and ejection mechanisms to ensure efficient production and consistent part quality.

-

Assembly Considerations: Design parts for ease of assembly and integration into larger assemblies. Minimize the need for additional assembly steps or secondary operations by incorporating features like snap fits, self-aligning features, or integrated fastening features into the part design.

-

Testing and Validation: Prototype and test part designs to validate functionality, fit, and performance before proceeding to mass production. Use rapid prototyping techniques and functional testing to identify and address potential issues early in the design process.

By incorporating these considerations into the design process, engineers can optimize part designs for micro molding, ensuring efficient production of high-quality, precision-molded components for a wide range of applications.

The application for plastic micro injection molding

Plastic micro injection molding is a specialized manufacturing process used to produce small, intricate, and precise plastic parts with dimensions typically ranging from micrometers to a few millimeters. This process finds application in various industries where miniature components are required. Some common applications of plastic micro injection molding include:

-

Medical Devices:

- Micro injection molding is extensively used in the medical industry to manufacture small components for devices such as catheters, endoscopes, surgical instruments, drug delivery systems, and implantable devices.

- Examples of micro-molded medical components include microfluidic devices, micro connectors, micro valves, and microfluidic manifolds.

-

Electronics and Consumer Electronics:

- Micro injection molding is employed in the electronics industry to produce miniature components for smartphones, tablets, wearables, hearing aids, microphones, and sensors.

- Examples of micro-molded electronic components include connectors, micro switches, micro lenses for cameras, microfluidic chips for lab-on-a-chip systems, and micro speaker components.

-

Automotive and Aerospace:

- Micro injection molding is used in automotive and aerospace applications to manufacture small, lightweight components for vehicles, aircraft, and spacecraft.

- Examples include micro gears, micro connectors, microfluidic manifolds, micro switches, and micro sensors used in automotive sensors, fuel injection systems, airbag deployment systems, and aerospace instrumentation.

-

Microfluidics and Lab-on-a-Chip Devices:

- Micro injection molding plays a crucial role in the fabrication of microfluidic devices and lab-on-a-chip systems for applications such as medical diagnostics, drug discovery, chemical analysis, and environmental monitoring.

- These devices consist of intricate microchannels, valves, mixers, and reaction chambers fabricated using micro injection molding techniques.

-

Optics and Photonics:

- Micro injection molding is utilized in the optics and photonics industry to produce miniature optical components such as lenses, prisms, diffusers, and light guides for applications including cameras, projectors, sensors, and telecommunications equipment.

- Micro injection molding enables the fabrication of precision optical components with complex geometries and tight tolerances.

-

Microfluidic-based Drug Delivery Systems:

- Micro injection molding is used to manufacture components for microfluidic drug delivery systems, including microneedles, microreservoirs, microfluidic cartridges, and drug delivery implants.

- These systems enable precise control over drug dosage, delivery rates, and administration schedules for personalized medicine and targeted therapies.

-

Micro Packaging and Micro Assembly:

- Micro injection molding is employed in micro packaging and micro assembly applications to produce small components for packaging, sealing, and assembly of microelectronic devices, MEMS devices, and medical implants.

- Micro-molded components such as micro clips, micro springs, micro hinges, and micro interconnects are used to assemble miniature products and devices.

Overall, plastic micro injection molding enables the production of miniature plastic parts with high precision, complexity, and repeatability, making it an essential manufacturing technology in industries requiring miniaturization, precision engineering, and advanced functionality.

The new develop for plastic micro injection molding technology

Plastic micro injection molding technology continues to evolve, driven by advancements in materials, equipment, processes, and applications. Here are some recent developments in plastic micro injection molding technology:

-

Advanced Materials:

- Development of new materials optimized for micro injection molding applications, including high-performance thermoplastics, engineering-grade resins, and liquid silicone rubber (LSR) formulations.

- Introduction of bio-based and biocompatible materials suitable for medical and biotechnological applications, offering improved sustainability and compatibility with biological systems.

-

Microscale Tooling and Molding Equipment:

- Advancements in microscale tooling technologies, including micro milling, micro EDM (electrical discharge machining), and micro grinding techniques, enabling the fabrication of highly precise molds with intricate features and microstructures.

- Introduction of micro injection molding machines with enhanced capabilities for controlling injection parameters, such as shot size, injection speed, and melt temperature, to achieve precise molding of micro-sized parts.

-

Microfluidics and Lab-on-a-Chip Integration:

- Integration of microfluidic channels, valves, mixers, and sensors into plastic micro injection molded components for lab-on-a-chip devices, point-of-care diagnostics, drug delivery systems, and chemical analysis applications.

- Development of microfluidic-based microreactors and microfluidic cartridges for synthesis, screening, and analysis of chemical compounds and biomolecules.

-

Miniaturization and Functional Integration:

- Miniaturization of complex mechanical, electrical, and optical components through plastic micro injection molding, allowing for the integration of multiple functions into a single micro-sized part.

- Development of micro-electromechanical systems (MEMS) and micro-optoelectromechanical systems (MOEMS) enabled by micro injection molding for applications in sensors, actuators, optical switches, and microfluidic devices.

-

High-Speed and High-Volume Production:

- Optimization of micro injection molding processes for high-speed and high-volume production of micro-sized parts, achieved through advances in mold design, machine automation, and process monitoring.

- Implementation of multi-cavity molds, rotary molds, and micro-injection-compression molding techniques to increase throughput and reduce cycle times in micro molding operations.

-

Microstructure Control and Surface Modification:

- Development of techniques for controlling microstructure and surface properties of plastic micro injection molded parts, including micro-texturing, nano-imprinting, and surface functionalization methods.

- Integration of surface modifications for enhancing biocompatibility, adhesion, lubricity, and optical properties of micro-sized components used in medical, automotive, and consumer electronics applications.

-

Additive Manufacturing Integration:

- Integration of additive manufacturing technologies such as 3D printing and micro-scale additive manufacturing into plastic micro injection molding processes, enabling rapid prototyping, tooling fabrication, and customization of micro-sized parts.

-

Simulation and Modeling Tools:

- Advancements in simulation and modeling software tailored for micro injection molding, allowing for virtual optimization of mold designs, process parameters, and material selection to predict and minimize defects, warpage, and molding stresses.

These developments in plastic micro injection molding technology are driving innovation across various industries, enabling the production of miniature, precise, and functional plastic components for a wide range of applications, from medical devices and electronics to automotive systems and microfluidic devices. Continued research and development efforts are expected to further enhance the capabilities and accessibility of micro injection molding technology in the coming years.

This is just a partial overview of micro molding & micro injection. Are they the right solutions for you? Not sure how to apply them to your next project? Just contact our technical experts and we can offer helpful advice about how to get the best results from both processes.